Services

Where expertise meets reliability

At McGrath Engineering, we are committed to delivering excellence and innovation in every project. Our comprehensive range of services is designed to meet the unique needs of the food and pharmaceutical industries, ensuring precise, efficient, and reliable solutions. Explore how our specialised services can help elevate your operations to new standards of quality and performance.

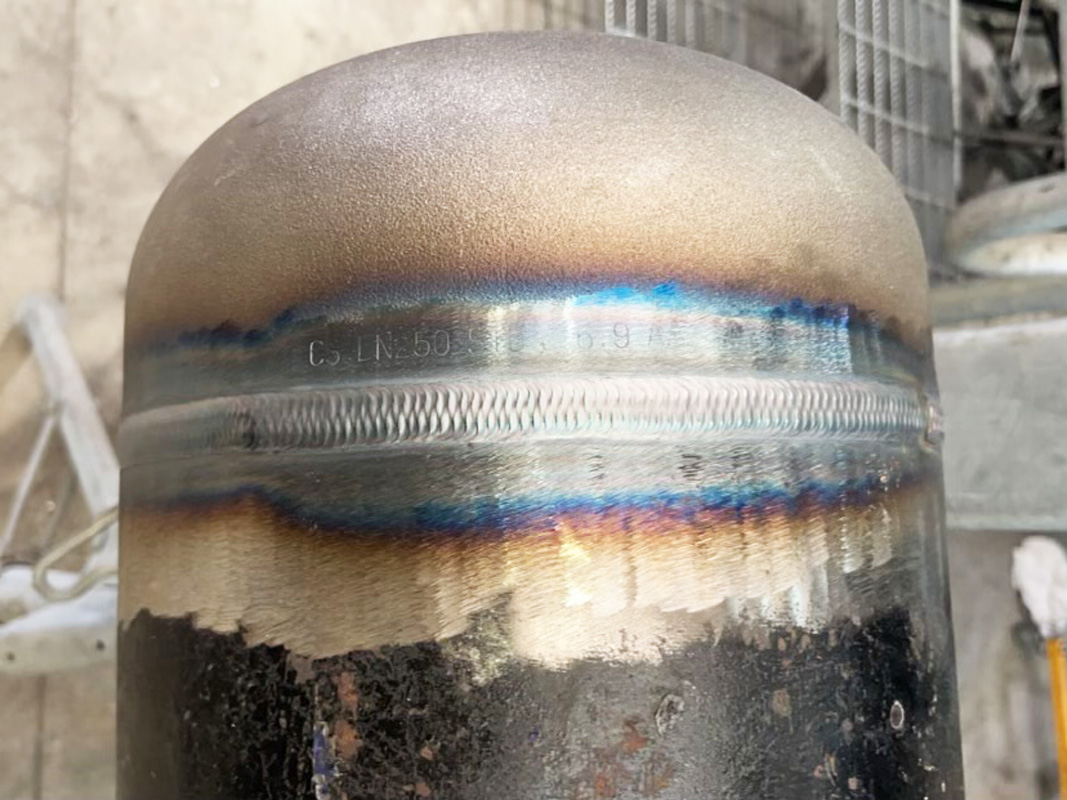

Sanitary stainless tube welding

McGrath engineering can work with our clients to provide 100% sanitary welds in their process pipework.

This tube welding process minimizes the possibility of contamination. It involves creating a fully penetrated weld that accesses the inside of the tube and forms a smooth surface. Our welds will be purged with a highly pure inert gas (such as argon) to remove the hazardous gases released and built up during the welding process. Sanitary tube welding is used for applications that require high sanitary standards, such as food, beverage, pharmaceutical, and biotechnology industries.

All our welds are passivated to ensure the removal of weld discoloration and remove contaminants which are potential corrosion sites.

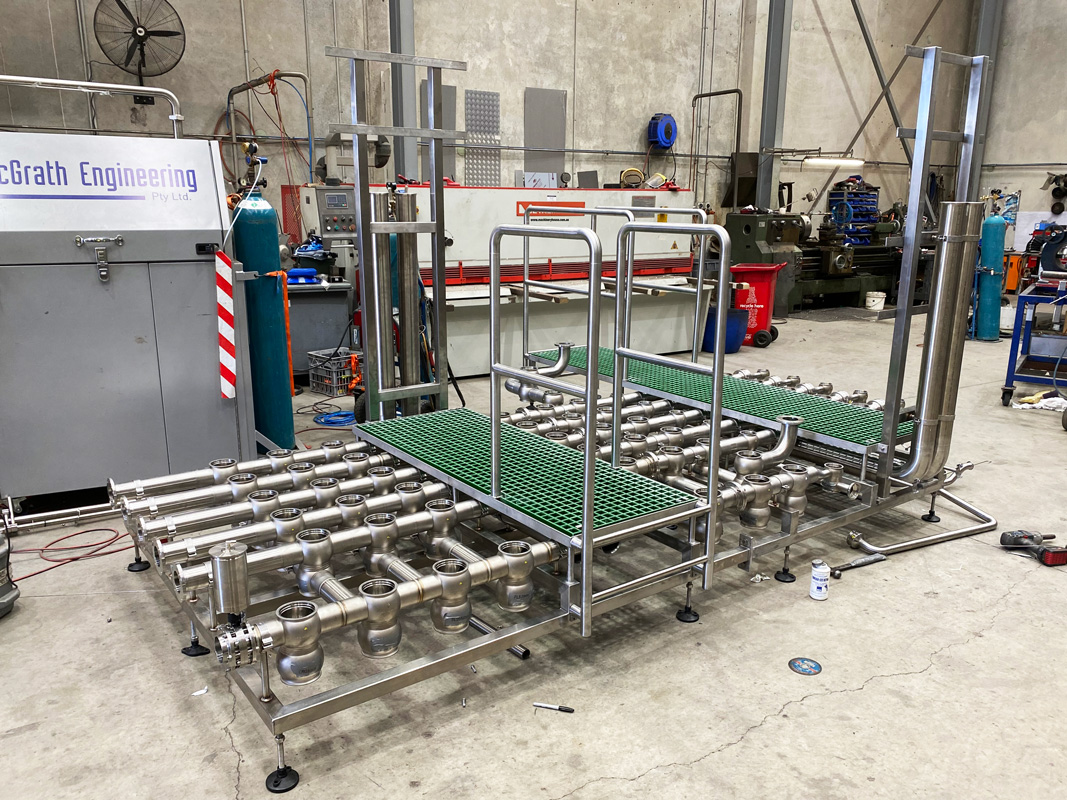

Skid fabrication

McGrath Engineering has had the opportunity to fabricate and install many skids that service the food, beverage, manufacturing and pharmaceutical industries. Ranging from water treatment, pasteuriser skids, CIP skids and filtration systems for various uses.

Our team have the extensive knowledge & experience to work with our clients from concept designs through to fabrication & installation.

Orbital welding

Looking for that extra assurance of quality on your project? McGrath engineering can provide orbital welding services to ensure consistent, full penetration welds on all joints.

Orbital welding is a technique whereby the welding tool is rotated through 360° (or 180° in double up welding) around a static workpiece. Originally developed to solve the problem of operator error in Tungsten Inert Gas (TIG) welding (also known as Gas Tungsten Arc Welding (GTAW)), and allow for a uniform weld around pipes and tubes, which can be difficult to achieve with manual welding processes.

Pipe spooling and coded welding

McGrath engineering offers fully qualified tradesman to fabricate your most difficult and complex pipe projects. Weather its mild steel, stainless steel (304 or 316) or something more exotic like super duplex McGrath can tackle the toughest projects to the highest standards.

We can ensure our welders comply with the relevant Australian Standards including AS3992, ISO, AS1554 andAS4041 and API and ASME 9.

Structural steel fabrication

McGrath engineering offer services in design, drafting, fabrication and installation of fixed platforms, walkways, stairways and ladders. All our work adheres to Australian standard AS1657.

We offer fabrication of mild steel, aluminium and stainless-steel structures. Flooring options and stair treads can include FRP grating, tread plate or welded mesh options.

On site installations

At McGrath we can offer our clients full project solutions. From the initiation and planning stage right through to implementation and commissioning we’ve got your project covered.

Our onsite services include:

- Tank, pump & skid installations – Including cranage, on site fabrication of connecting pipework and services and cut ins to existing lines.

- Mechanical & equipment installations – Including assistance with the installation of fillers, packers, conveyers and much more. We provide the design & fabrication of services droppers to machines for water, air, electrical and anything else required.

- Platforms, stairs & handrails – Weather its stainless or hot dipped galvanized McGrath supply and install your access solutions.

Project management solutions

Our project management team and site supervisors will ensure that your project is managed successfully. We can deliver turnkey installations for a range of jobs. With a high focus on safety and an excellent grasp of quality requirements our positive results speak for themselves through our proven track record. Through our wealth of industry experience we have the technical and practical skills to deliver project outcomes on time and within budget. We will liaise with stakeholders, so the job runs safely and smoothly to achieve optimum client satisfaction.

Looking for something a little more specific?

No matter the size or complexity, McGrath Engineering is here to assist with all your project needs. From initial concept to final installation, our team of experts is ready to deliver exceptional results. Contact us now to discuss your project and let us help you achieve your goals with our expert metal fabrication solutions.